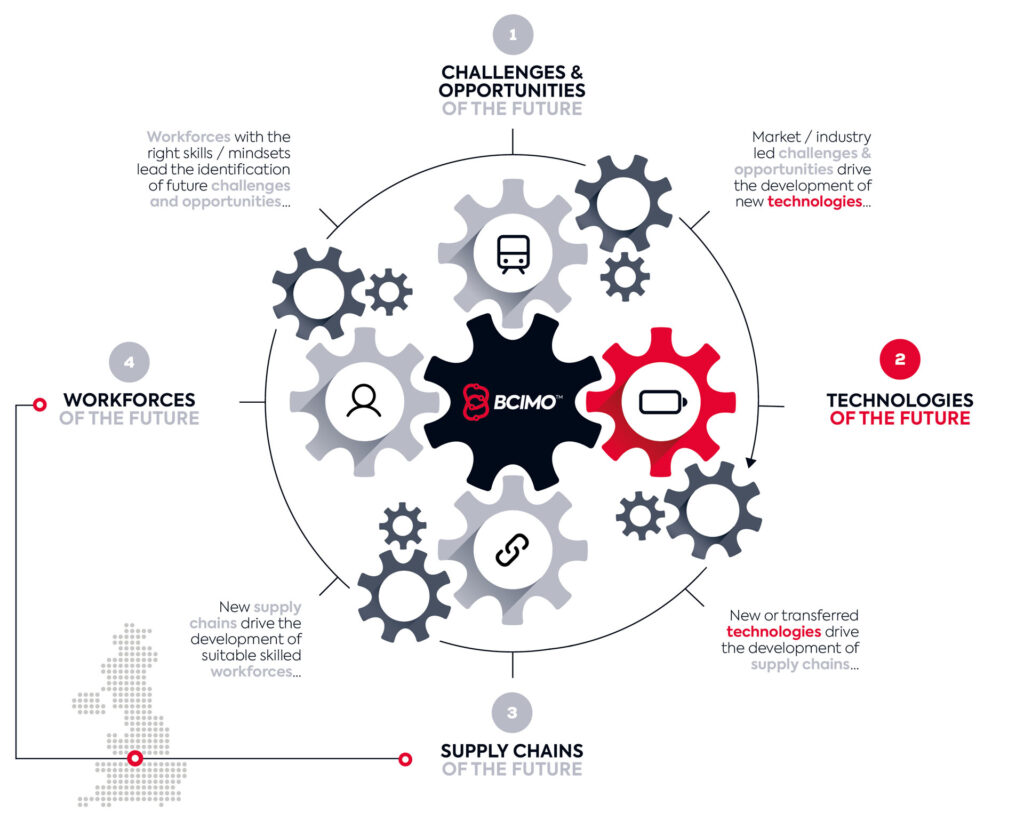

In October, BCIMO explored the first of its framework for innovation ‘cogs’, looking in-depth at challenges and opportunities within the rail industry, and how its new Commercial Investment Hub model will aim to facilitate innovation. This month it highlights the role of the second cog, through the work of the Clean Futures Accelerator, in bringing those innovative technologies to the fore.

Like many comparable sectors, the rail industry has roots that go far deeper than the tracks and trains we know and, whilst we celebrate 200 years of the modern railway next year, technologies that facilitated its birth are very much older. Indeed, the oldest constructed trackways found are in the southwest of the UK across a coastal plain known as the Somerset Levels, and date from the 38th century BC, with later documented examples in long-term use within the Greek and Roman civilisations. Early ‘rails’ here were carved into limestone, preventing wheeled vehicles pulled directly by men or animals from leaving the route; with a later funicular construction in Europe utilising installed wooden rails and a treadwheel, i.e., new ‘innovations’.

A further significant point of reflection is that the technologies we are familiar with did not originate in a space called ‘rail’. So, the emergence of our modern-day systems relied solely on the innovative and entrepreneurial impetus of individuals operating in other industries seeing the potential for other applications of their work. And whilst new innovations have also emerged to be exclusively deployed within rail, the origins of those ideas have likewise been sparked elsewhere, with many notable inventions over time being inspired by the most seemingly unlikely of daily occurrences and subsequent developmental thoughts – as the writer Mark Twain said, “there is no such thing as an original idea”.

All innovations were, as per the nature of BCIMO’s cog model though, inspired by challenges and opportunities within the industry and, as per the complex nature of that industry, potential for new technologies is broad. Literally from the ground up, it includes all elements of infrastructure, from rails to roof, plus rolling stock, alongside the myriad systems and services involved in the manufacture and maintenance of the railways from day-to-day. But again, as for other industries, it’s essential that the focus is always beyond the present, considering its needs into the future in context of a variety of shifting interdependent environmental landscapes.

And whilst technologies include the tangible products and visible services of the rail industry and its complex supply chain, innovation can also be encompassed within the systems and processes needed to manufacture and deliver a business’ portfolio. Where elements are combined, such as hardware and software, it could be applicable to both or, where one is changed but the other not – not yet, or as quickly – innovation is still happening, remembering that transitional technologies are equally as viable as transformational. It is also assumed that true innovation is only the ‘new’, but again technologies can be developed for other needs or deployed in a different way.

This heritage of cross-sector reimagining and redeployment has continued within rail, with the inspiration for BCIMO’s home – the Very Light Rail National Innovation Centre – emerging from existing technologies within the automotive industry to create something of a hybrid ‘car on rails’ application. And further, as discussions intensify within the transport industry on the need to shift from a single mode view to an interconnected, multimodal system based on the holistic nature of passenger and freight journeys, this imperative for cross-sector technological application and innovator collaboration will likewise intensify.

In the first cohort of the Clean Futures Accelerator, the SMEs and technical team working with them at BCIMO envisaged such opportunities within two distinct concepts. The first was the potential to use a single platform to showcase multiple innovations – in this case the newly renovated former-Midland Metro T69 tram – offering industry partners insight into how different technologies may be utilised within a cumulative space. Two of the innovations, from BoxTube and Varamis Rail, were then linked conceptually to a third, from Coexlion, to illustrate a ‘last-mile freight delivery’ proposition as a broader interoperable system for the industry to consider.

Sourced as a component supplier for BoxTube’s rapid loading system, then opened dialogue on innovation with applications in rail for Alucast, a traditional Black Country manufacturer, who applied and were successful for Cohort 2. Now, as part of the technical discussions, they will be producing aluminium components using a new high-strength, low-carbon material for GBR Rail’s waste recycling technology; whilst, once again, the T69 tram will be a ‘demonstration day’ centrepiece for deployment of Grinstry Rail’s passenger comfort module technology and Moonbility’s AI-powered software to enhance disability access.

Out on the track, negotiations are also continuing apace on a variety of collaborations, with potential for the energy from a Treeva trackside wind turbine to power Integrated Systems Engineering’s in-tunnel 5G connectivity technology; and for this in turn to provide a stable signal for Moonbility. Treeva also have the potential to install a turbine on the overhead line equipment structure being built on site by Composite Braiding, using components made from and with sustainable materials and processes – an SME who were also part of Clean Future’s first year, producing components for the automotive sector via project partner, Coventry University.

In essence, as long as rail has existed and now evolves into the future, there will continue to be challenges in need of solutions and opportunities for innovative ideas that haven’t even been considered. Although wooden rails and a treadwheel are far from the technologies we envision today, with new materials, both raw and reused, new processes to manufacture and engineer, new capabilities to operate and manage, and at the heart of all: new ideas, still emerging, it is the technologies of tomorrow on which we focus, with a vision for the rail industry yet to come.

Programme Manager for Clean Futures and technical lead, Matt Wood, said: “The rail industry faces a broad range of challenges, both now and in the future, so it’s essential that technologies continue to be developed to address these, which is something that Clean Futures is focused on delivering. The level and variety of innovation in Cohort 1 was amazing, however Cohort 2 raises the bar again and provides the ability for the SME innovations to complement each other and enhance functionality even further. In Cohort 1 they formed a vertical supply chain, in Cohort 2 they improve the stand alone, self-powered, autonomous, virtually maintenance-free innovation, and we look forward to seeing these develop within the programme, so that we can showcase them to industry on Demo Day.”

For more information on BCIMO or the Clean Futures programme please visit the BCIMO website or Contact Us to make an enquiry / sign up to our mailing list.