REO UK Ltd, a leader in designing and manufacturing cutting-edge rail components, is pleased to announce a significant upgrade. Starting in 2025, our signature ‘Red’ coating, known for its high performance, will be replaced with a more advanced ‘Anthracite’ grey material. This change brings numerous benefits, including improved sustainability, safety, and durability, making it a superior choice for our rail components.

REO has been using a red high-performance silicone material for several years. Its superior sealing and bonding capabilities have made it a core component of REO’s advancement in the rail industry’s evolving push for reliability and efficiency.

As the rail industry increasingly focuses on sustainability, safety, and durability, REO Train Technologies has identified an alternative that meets or exceeds the demanding standards required in rail applications and improves ecological impact. The new silicon-based material is chemically inert, which means it does not release harmful substances into the environment over time. This makes it much safer for environmentally sensitive applications than materials that might degrade and release toxins.

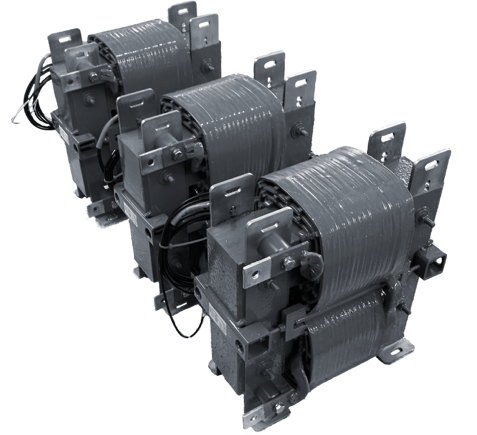

The new material, known for its flexibility, temperature resistance, and high durability, is ideal for protecting chokes and transformers from the myriad external issues they can be exposed to.

- Enhanced Vibration Resistance: In rail applications, components are subjected to constant vibration and mechanical stress. The material provides superior damping capabilities, ensuring the longevity and stability of sensitive electrical components.

- Temperature Stability: Withstanding temperatures up to 180°C, the material’s thermal stability makes it ideal for rail environments where components can be exposed to varying and extreme conditions.

- Superior Sealing for Safety: The material forms a flexible seal that protects against moisture ingress. This ensures that REO’s chokes and transformers remain operational in wet or humid environments, a critical factor for rail systems operating in diverse climates.

Rail applications are governed by stringent safety and operational standards. REO has ensured that all products utilising the new material meet the latest industry safety regulations, including EN 45545-2, which sets fire safety standards for materials used in rail vehicles.

By using this material to produce its inductive components, REO increases the longevity of its products, ensuring they withstand extreme temperatures, vibrations, and environmental stressors (UV radiation, ozone, rain, snow, etc).

“This material has become a cornerstone of our advanced component solutions for the rail sector,” said Steve Hughes, Director at REO UK Ltd. “Its unique combination of flexibility, durability, and resistance to environmental stresses makes it a natural fit for the rail industry’s demanding conditions. This ensures that our transformers and chokes not only meet but exceed our client’s expectations in terms of performance and safety.”

If you would like to find out more about the wide range of products REO UK offers for use in train and railway applications, please visit https://www.reo.co.uk/solution/rail-solutions/