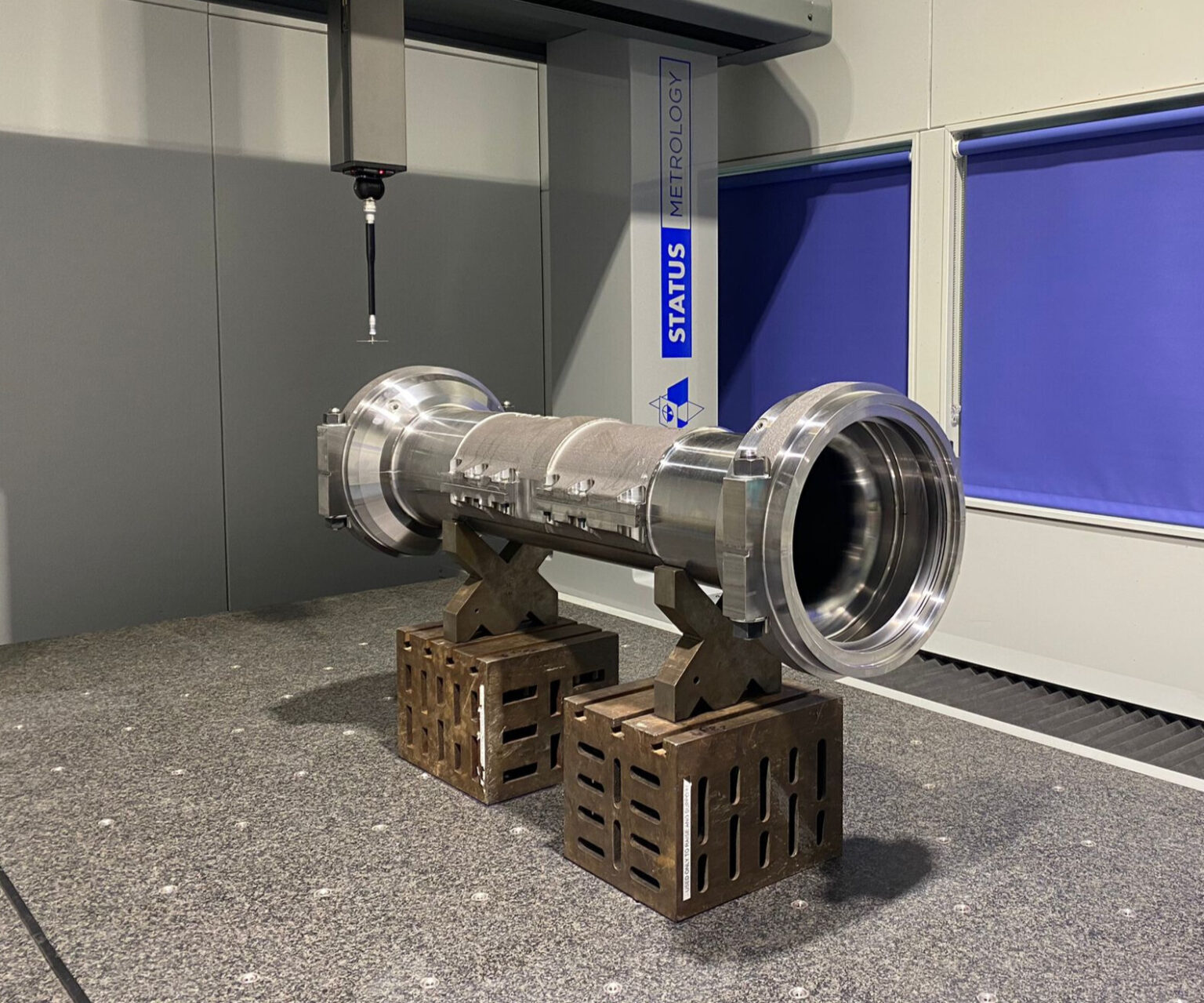

ZF Services UK is enhancing its rail division through significant growth at its Nottingham Centre of Competence, reinforcing its position as a global leader in rail engineering. The Centre is pivotal in the overhaul, repair and preventive maintenance of ZF and multi-brand driveline and bogie systems. It specialises in reverse engineering and re-engineering gearboxes, final drives, dampers and bogies, ensuring all parts meet ZF’s stringent standards.

This expansion reflects ZF’s success in the UK market, driven by the increased demand for high-quality rail solutions. The Centre focuses on sustainable practices, such as the reverse engineering and multi-brand overhaul of gearboxes, bogies, and dampers, emphasising repair and reuse over replacement. With its RISAS certification, the Nottingham facility upholds ZF’s dedication to quality and sustainability, offering a comprehensive approach to supporting all gearbox brands.

ZF’s commitment to innovation and the environment is further highlighted by the development of the EcoWorld 2 gearbox at its R&D facility based in Friedrichshafen, Germany, and has been designed to improve fuel consumption and reduce emissions.

The Centre of Competence’s advanced capabilities in gear design, reclamation, and reverse engineering position ZF as a leading specialist in rail engineering, providing a comprehensive multi-brand offering to meet the evolving needs of the industry.

For more information about ZF’s rail solutions and the Centre of Competence, please visit here.