The unveiling of the new Stadler subway series JK marks a significant step in developing Berlin’s rail network. The existing rolling stock is over three decades old, and the new train represents a leap into a new era of technology.

The initial test cars will undergo trials using the Berlin metro network in January 2024 before being put into regular passenger service in late summer 2024. This new subway series represents a significant advancement in rail technology and lays the groundwork for further innovations in the future.

While there are hardly any noticeable external differences, the JK series impresses with many innovations from a passenger’s point of view. Improved doorways and enhanced customer information areas give a more spacious feel and generous standing room. New vertical handrails render ceiling bars unnecessary, and unique bent handrails facilitate easier passage for wheelchair users. Additionally, space-saving screens and integrated size indicators on signs indicating spaces for disabled persons are part of the modernized interior.

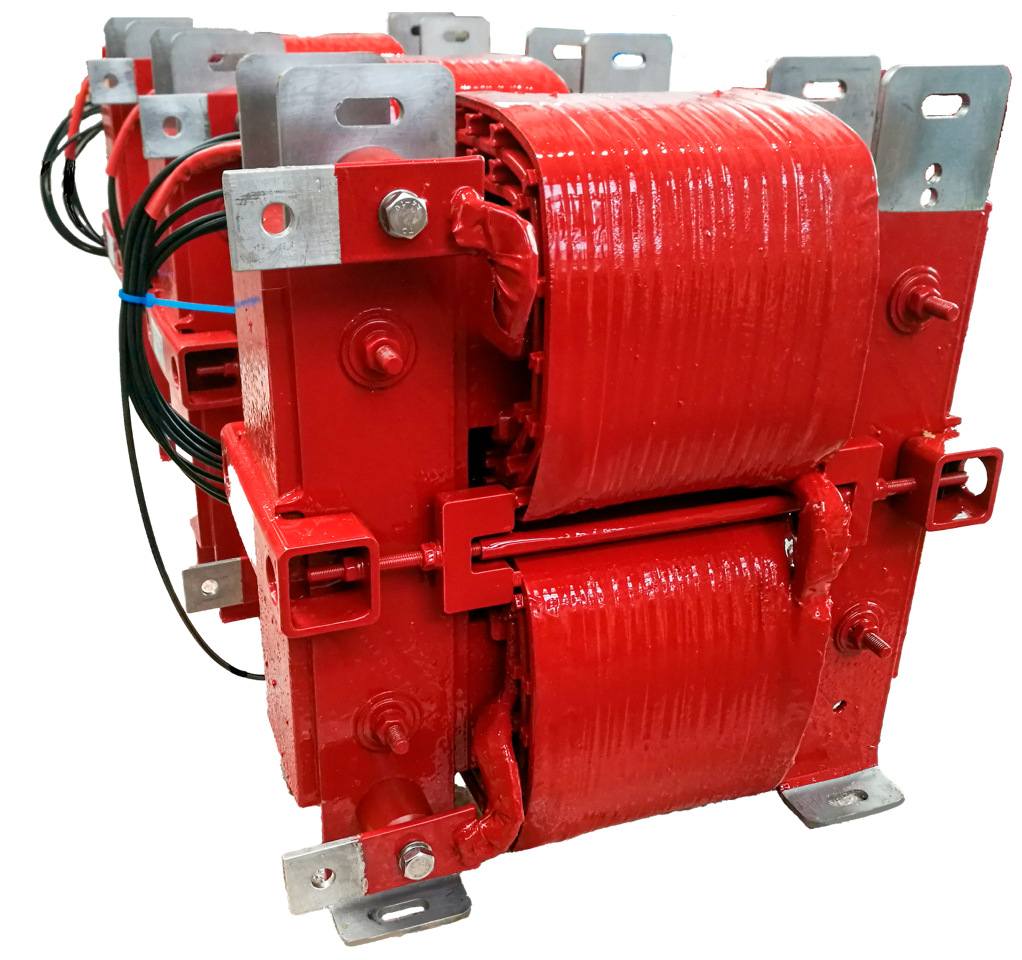

On the power side, the collaboration between REO TPM and ABB drives helped accelerate significant technological advancements. REO has established itself as a prominent player in designing and manufacturing chokes and inductors, specifically for the railway industry. Their expertise lies in crafting components that meet the rigorous demands of this sector, ensuring reliability, durability, and optimal performance in railway applications.

When it comes to the types of chokes and inductors they offer, REO covers a spectrum of variants to suit diverse needs within the railway industry:

Line Chokes: These chokes are essential for mitigating harmonics and filtering electromagnetic interference (EMI) from the power supply lines in railway systems. They ensure stable and clean power delivery, crucial for the smooth operation of various railway equipment, such as traction systems, signaling devices, and communication networks.

Traction Chokes: Transaction chokes are pivotal in electric and hybrid locomotives, specifically designed to handle high currents and voltages associated with traction systems. They regulate and control the flow of electrical energy, optimizing efficiency and minimizing losses during acceleration, deceleration, and braking processes.

Filter Chokes: Railway environments often entail exposure to external disturbances and electromagnetic noise. Filter chokes act as barriers against these interferences, maintaining signal integrity and safeguarding sensitive electronic circuits in onboard control systems, signalling apparatus, and communication interfaces.

DC Link Chokes: In electric railway systems utilizing DC power distribution, DC link chokes are vital for smoothing the rectified output from power converters. By reducing ripple currents and voltage fluctuations, these chokes contribute to the stability and reliability of the DC power supply, ensuring consistent performance across various operational conditions.

Auxiliary Chokes: Beyond the primary power and traction systems, auxiliary chokes are used in auxiliary equipment and subsystems within railway vehicles. These chokes aid in voltage regulation, noise suppression, and interference rejection, enhancing the overall efficiency and functionality of auxiliary systems like HVAC (Heating, Ventilation, and Air Conditioning), lighting, and onboard electronics.

REO’s comprehensive understanding of the unique requirements and challenges in the railway industry allows them to engineer chokes and inductors that meet stringent quality standards and regulatory specifications. Through continuous innovation and collaboration with railway operators and manufacturers, RE AG remains at the forefront of delivering cutting-edge solutions for powering and controlling railway systems with utmost reliability and efficiency.

For example, for this project, the carriages are designed to operate at a maximum speed of 70 km/hr, so the chokes must be robust, able to withstand significant levels of shock and vibration and provide excellent EMC performance. A special ferromagnetic enclosure was designed to minimize electromagnetic interference and provide the required durability levels for this demanding application, enhancing the subway’s safety and reliability.

In addition, the units are specially coated to improve insulation and reduce creepage and clearance distances, allowing the physical size and weight to be reduced, an essential factor in modern railways.

If you would like to find out more about REO’s capabilities in the field of chokes, please visit https://www.reo.co.uk/transportation-converter-solutions