Engineers from the University of Sheffield Advanced Manufacturing Research Centre (AMRC) are collaborating with East Midland Railways (EMR), a fellow Rail Forum member, to look at the viability of manufacturing simulation tools to improve the efficiency and effectiveness of rail depot operations.

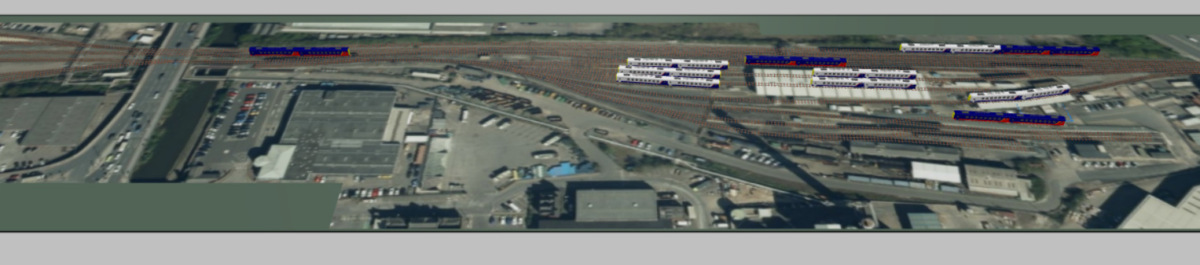

The project, made possible by the Network Rail Performance Improvement Fund, has seen AMRC engineers work closely with EMR operations staff to record the rules, processes and timings to develop a representative model of their Nottingham Eastcroft depot.

James Hawke, IT and systems programme manager at EMR, said: “This model provides a virtual representation of activities in a 24-hour period and assists the current ‘beat-rate’ exercise. This model will add a dimension of scenario planning that was previously difficult and time consuming to accomplish. The net result being more efficient depot operations, improved unit availability and improved service for the public.”

Richard Gardiner, senior innovation fellow at the AMRC, added: “These simulation tools have the potential to enable EMR to plan, stress test and simulate operational scenarios in a fraction of the time it would using conventional methods.”

The project is currently going through a detailed validation period, after which it will be trialled as an operational tool with EMR. If the project shows potential, the next phase will be to connect the simulation to live inputs – including timetable and depot movements, among other factors – to evolve the tool into a live digital twin of the working depot environment.