GBR-Rail’s Cleartrak, a novel train toilet treatment system, has been awarded SMART grant funding through Innovate UK.

10,000 train toilets operate on the GB Network alone and each train toilet discharges 80 tonnes of waste into the sewage network annually.

Cleartrak has been designed to reduce the whole life, environmental and social costs of maintaining trains with toilets, whilst also benefitting the railways with increased train availability, route flexibility and passenger satisfaction.

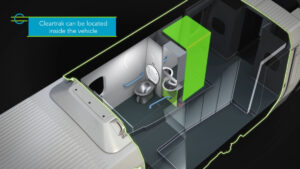

With Cleartrak wastewater is not stored on-board but recycled for reuse in handwashing and flushing. Solid waste is processed into an inert biochar, which can be emptied once every six weeks in any location.

Operating independently of the sewage network, without the need for specialist infrastructure and frequent emptying, the whole life costs of maintaining trains with toilets are halved, water wastage is reduced by 95% and GHGs by 35%.

Tim Brown, GBR-Rail MD commented, “This SMART funding will enable us to validate Cleartrak’s design and performance, through extensive real world on train testing, as a safe and reliable train toilet wastewater treatment and recycling technology for global use, prior to commercialisation in late September 2023.”

Notes to Editor

GBR-Rail Ltd, based in Rotherham, has specialised in rolling stock maintenance equipment since 2009. It is this in depth understanding of all the pain points in depot production that has been the driver behind Cleartrak’s R&D.

Each CET toilet discharges 80 tonnes of waste into the sewage network annually. Cleartrak’s discharge of ¼ tonne annually does not go into the sewage network.

GBR-Rail’s Cleartrak received First of a Kind Funding in 2020 from the DfT through the Innovate UK SBRI Funding Competition

GBR-Rail’s Safe Waste Technology (SWT) deployed in Cleartrak is scalable for use in other transportation modes, hotels, hospitals, isolated communities and disaster zones.

Link to Press Release on Website

For further information please contact: